Atomically Thin Amorphous Carbon Films Synthesized from Solution Precursor

Authors: Fufei An, Congjun Wang, Viet Hung Pham, Albina Borisevich, Jiangchao Qian, Kaijun Yin, Saran Pidaparthy, Brian Robinson, Ang-Sheng Chou, Junseok Lee, Jennifer Weidman, Sittichai Natesakhawat, Han Wang, André Schleife, Jian-Min Zuo, Christopher Matranga, and Qing Cao*

Highlighted by DoE, MSN, ScienceDaily, Nanowerk, TechXplore, Technology Networks, Science Times, Innovations Report, Hackster, and more

Background

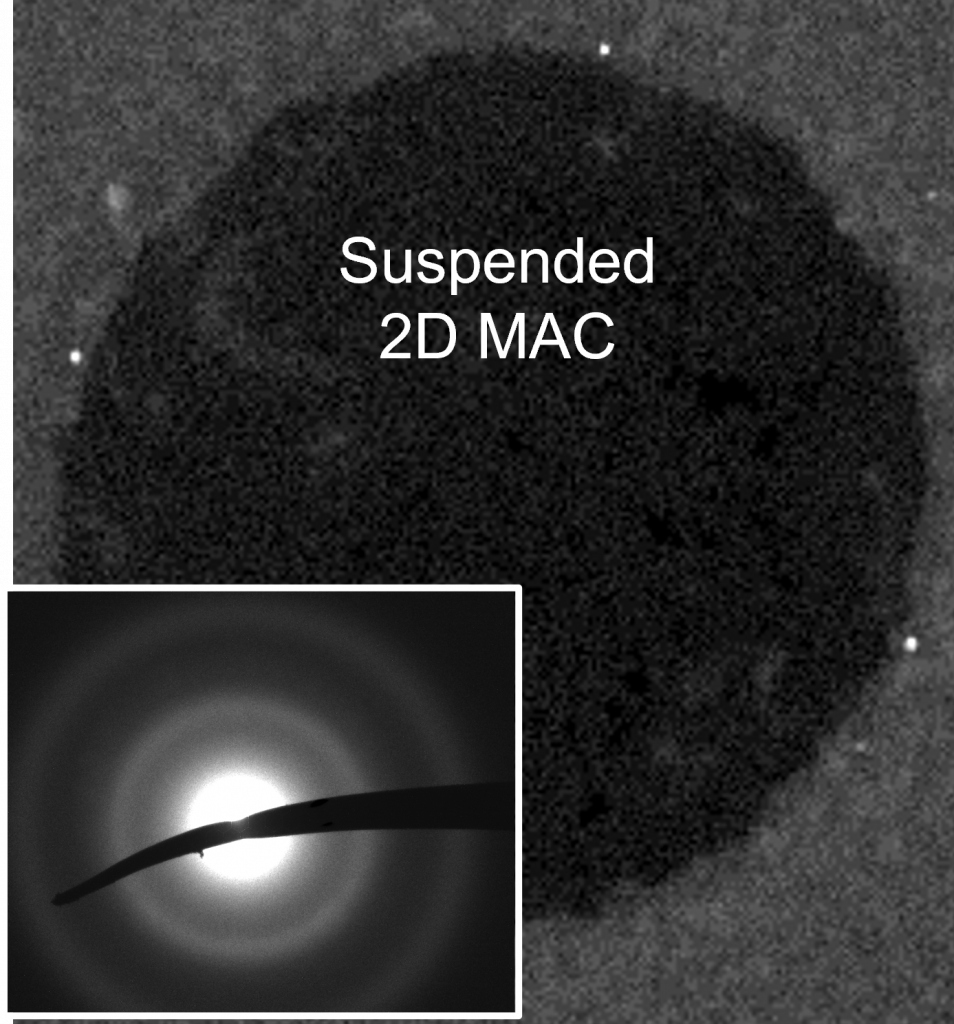

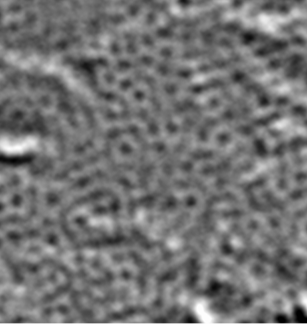

Atomically thin materials with their distinctive physical properties have drawn lots of interest from the aspects of both fundamental studies and practical applications. Crystalline graphene and two-dimensional transition-metal chalcogenides with thickness down to one to a few atomic layers can be readily prepared through either exfoliation from their van der Waals bulks or chemical vapor deposition (CVD) growth. However, the synthesis of amorphous materials with thickness approaching the atomic limit is difficult since amorphous solids generally do not have well-defined van der Waals gaps while non-crystalline phases are thermodynamically unstable with the tendency to transform into crystalline phases under typical CVD growth conditions. Current approaches to prepare atomically thin amorphous films rely on the adoption of plasma-enhanced CVD or pulsed-laser deposition, where the power provided by the excited species in plasma or the energetic pulsed laser can decompose the molecular precursors and lead to the formation of continuous films with confined thickness on flat catalytic surfaces but is insufficient to promote crystallization. For both methods, the spatial uniformity and area coverage of the prepared ultrathin two-dimensional (2D) amorphous films are limited, and the film thickness cannot be precisely controlled with atomic level of precision, especially beyond the first monolayer. These limitations have so far prevented their adoption in functional application demonstrations which require films with large-area homogeneity and precisely tunable thickness from monolayer to multilayers, ideally synthesized directly on device substrates.

Atomically thin Amorphous Carbon

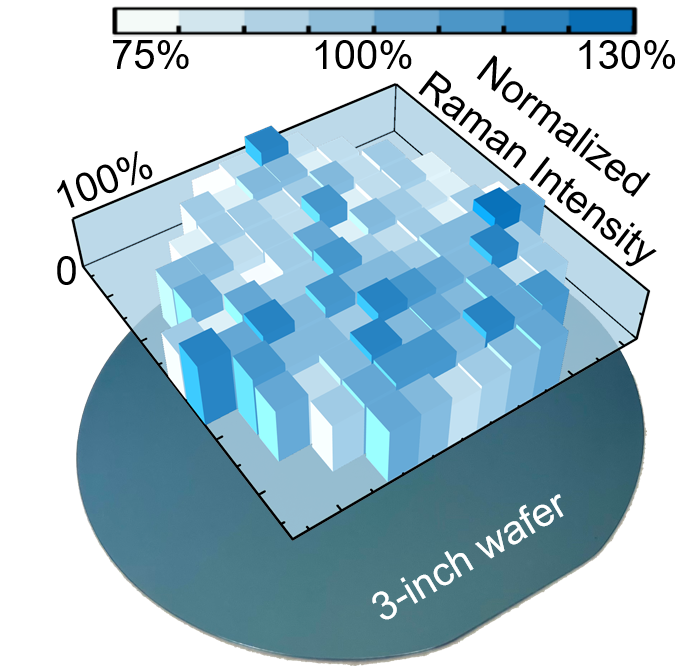

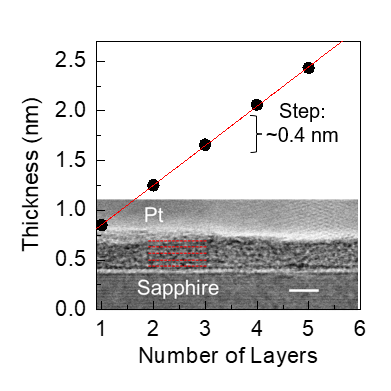

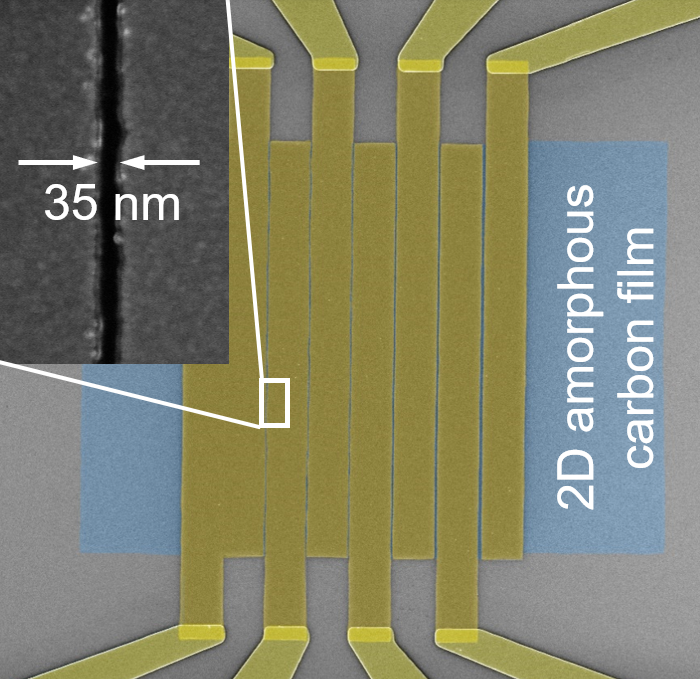

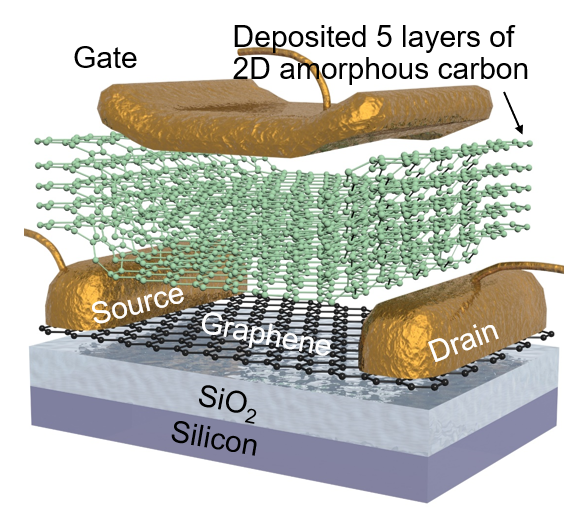

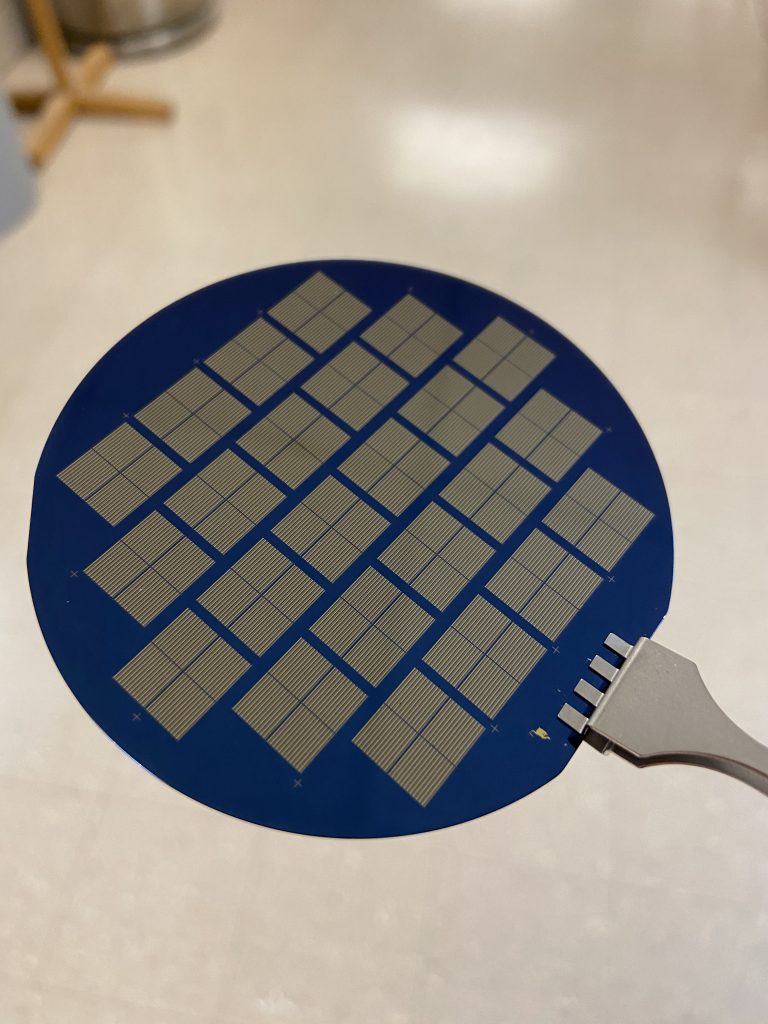

Here we report the wafer-scale synthesis of ultrathin amorphous carbon films with thickness down to 1–2 atomic layers from solution-processable carbon-dot precursors directly on non-catalytic substrates. The prepared one layer of coalesced carbon dots is an atomically thin, mechanically strong amorphous film predominantly composted of sp2 carbon with low surface dangling bond density, and their few-layer assemblies are robust, high-capacitance nanodielectrics with low leakage current density and high breakdown field strength. This synthesis strategy is distinct from catalytic vacuum deposition from gas-phase molecular precursors, with substantial advantages in enabling a solution-deposition process that is not only scalable but can be repeated in a layer-by-layer fashion for producing freestanding membranes from 1–2 atomic layers to multi-layered stacks with precisely controlled nanometer thickness. The achieved unprecedented macroscopic uniformity, atomic-level thickness control, and processability further allow engineered incorporation of prepared ultrathin amorphous carbon films as dielectric in functional electronic devices, where their unique structure and properties were exploited to enable improved device performances.

Nanoelectronics Applications

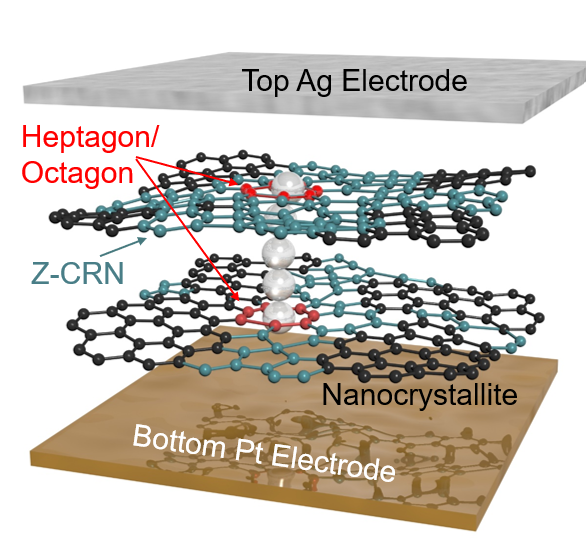

Resulting from their unique amorphous atomic structures, the prepared atomically thin amorphous carbon demonstrates robust dielectric properties with resistivity higher than 109 Ωꞏcm and dielectric strength above 20 MVꞏcm-1. When utilized as gate dielectrics in 2D transistors, ultra-thin amorphous carbon films help to achieve a low leakage current density below 10-4 Aꞏcm-2 with an extremely scaled thickness down to three atomic layers (~1.6 nm) for enhanced electrostatic coupling. Meanwhile, their dangling-bond-free van der Waals interface with graphene and MoS2 leads to mobility twice as high as that of 2D devices employing SiO2 or Si3N4. When implemented as ion transport media in memristors, the ultrathinness of the amorphous carbon bilayers enables forming-free operations of non-volatile memory cells with low voltage (<0.4 V), fast switching time (<20 ns), and low energy consumption (<20 fJ per operation), without sacrificing endurance and retention. The large-number rings from the amorphous structure provide well-defined pathways for the filament formation to minimize device spatiotemporal variability.

Links for Original Paper: https://doi.org/10.1038/s44172-023-00141-9

Editors' Choice 2024 from Communications Engineering:

Related News:

"Coal-derived Carbon Material Improves Performance and Efficiency of Computer Microelectronic Devices" NETL, December 20, 2023

"Better electronics from coal" TechXplore, January 3, 2024

"New study discovers coal’s unexpected role in next-gen microelectronics", Interesting Engineering, January 4, 2024

"Better electronics from coal", Science Daily, January 3, 2024

"Better microelectronics from coal", Nanowerk, January 3, 2024

"Better electronics from coal", Environmental News Network, January 3, 2024

"From Mines to Megahertz", Hackster, January 4, 2024

"Coal: The Future of Microelectronics", Peoples Post Media, January 4, 2024

"Scientists find way to turn coal into cutting-edge electronics", Knowridge Science Report, January 4, 2024

"Revolutionizing Electronics: How Coal Paves the Way for Next-Gen Devices", Medriva, January 4, 2024.

"Revolutionizing Electronics with Coal-Derived Carbon Layers: A Leap Towards Advanced Technologies", Future Headlines, January 5, 2024.

"Could Coal Be the Holy Grail of Nanoelectronics", Market Insights, January 16, 2024.

"University of Illinois Researchers Developing Coal-Based Semiconductors", Yahoo News, January 19, 2024.

"Coal: Don’t Burn It, Compute with It", IEEE Spectrum, January 24, 2024.